Technical Expertise

Our commitments in making Kaze no Mori, technical expertise & technology

Prolonged Fermentation at Low Temperatures

During the fermentation stage in sake production, two processes occur in parallel: the saccharification of starches to sugar by koji and the alcoholic fermentation of sugar to alcohol by yeast.

What is of importance here is the precise temperature control of this multiple parallel fermentation process. Without intervention, the temperature of the mash will naturally rise owing to yeast activity further boosted by minerals from the lightly polished rice and the hardwater used in brewing. If the temperature rises too much, fermentation will progress too much making it difficult to produce good sake.

At our brewery we use specially-designed proprietary tanks. Containing the temperature of the mash, softens the pace of the fermentation, which allows for a long period of fermentation of over 30 days. This makes it possible for us to brew sake that has volume and depth in taste yet is high in clarity with such aromas as white grape, pear and lychee.

Lightly Polished Rice

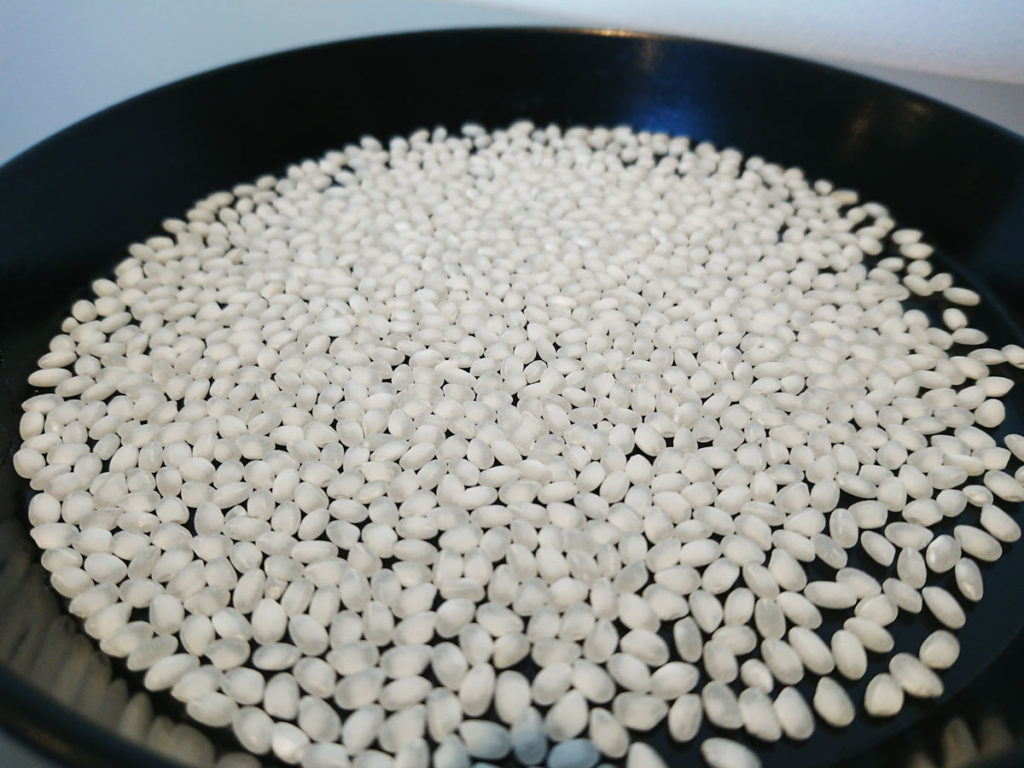

In order to appreciate and make full use of the inherent properties and nutrients of each rice variety, as well as the energy of the land, we focus our efforts on the use of lightly polished rice.

Conventionally, it is said that lightly polished rice does not dissolve easily. This is the reason sake made from highly polished rice, “dai-ginjo”, has been typically considered to be good. However, through the use of powerful koji we can dissolve lightly polished rice sufficiently, allowing us to bring out the full character of each rice varietal without squandering individuality.

Another reason is that since lightly polished rice is abundant in nutrients including minerals, the activity of the yeast is fueled to such an extent that it becomes very difficult to manage the fermentation process.

One solution to this issue is the use of ultra-fine bubbles (UFB) in washing the rice. As the name suggests, UFBs are very small bubbles. Generally, bubbles with diameters on the order of nanometres (less than 1 micrometre (1/1000mm)) are called UFBs. Washing the rice using water containing UFBs allows for all bran on the surface and in the grooves of each rice grain to be washed away thoroughly. This UFB technology is also used in the cleaning of semiconductors.

Employing such techniques, and precision control of the mash, unique qualities that can only arise from lower polishing rates, and a broad and dynamic palette of tastes can be enjoyed through Kaze no Mori.

Yeast No. 7

Type of yeast is a large factor influencing the characteristics of a sake.

In making Kaze no Mori we only use Yeast No. 7. This yeast is uniquely held by our brewery and has substantial fermentation power. It generates organic acids in abundance, when subjected to prolonged fermentation at low temperatures, and produces aroma compounds from a variety of aroma constituents which help bring about the fruity acidity and aromas unique to Kaze no Mori.

Unfiltered/Unpasteurized/No Added Water

Our objective is to deliver the taste of sake freshly pressed in its original form.

For this reason, we specialize in the production of sake which is neither filtered nor pasteurized and contains no added water post-pressing. The greatest appeal of unpasteurized sake is its thick, smooth and rich texture, as well as the fine changes in flavour that unveil over time.

However, producing unpasteurized sake comes with the difficulty of ensuring product stability and quality. To ensure stability in the quality of unpasteurized sake, measures for microbial control and minimizing oxidation must be meticulous, and storage temperatures must be kept as low as possible.

Microbial Control

We are rigorous in our measures to minimize the risk of microbial contamination. This is because we make unpasteurized sake.

Without undergoing the sterilization process that is pasteurization, there is the risk that microorganisms (such as hiochi bacteria) will be present in the sake. These microorganisms would impair the quality and taste of the sake. For all our unpasteurized products, we test for hiochi bacteria after pressing to ensure product quality.

Minimizing Oxidation

Oxidation occurs when sake mixes with the air and oxygen diffuses into the sake.

One measure we take to minimize oxidation is to avoid any form of clarification process using filters (filtration). While the use of filters to clarify sake can help balance it out, the original tastes, aromas and textures characterizing the sake just after pressing are lost. Moreover, the stirring action of pumps used in such processes fosters oxidation.

A second deterrent to oxidation lies in the structure of our building. Since our brewery is multistoried, it is possible to transfer sake from the sake press on the second floor to the storage tanks on the first floor without using a pump. Further still, when bottling the sake, we use our specially-designed proprietary bottling machine. The defining feature of this machine is that its nozzles move in tandem with the surface of the liquid during filling which reduces any bubbling of the sake.

In this way, by paying meticulous attention to the handling of our sake, we can minimize oxidation and deliver the tastes, aromas and textures of sake in their original form.

Temperature Control

At our brewery, pressed sake is stored at sub-zero temperatures to limit changes to taste that occur over time.

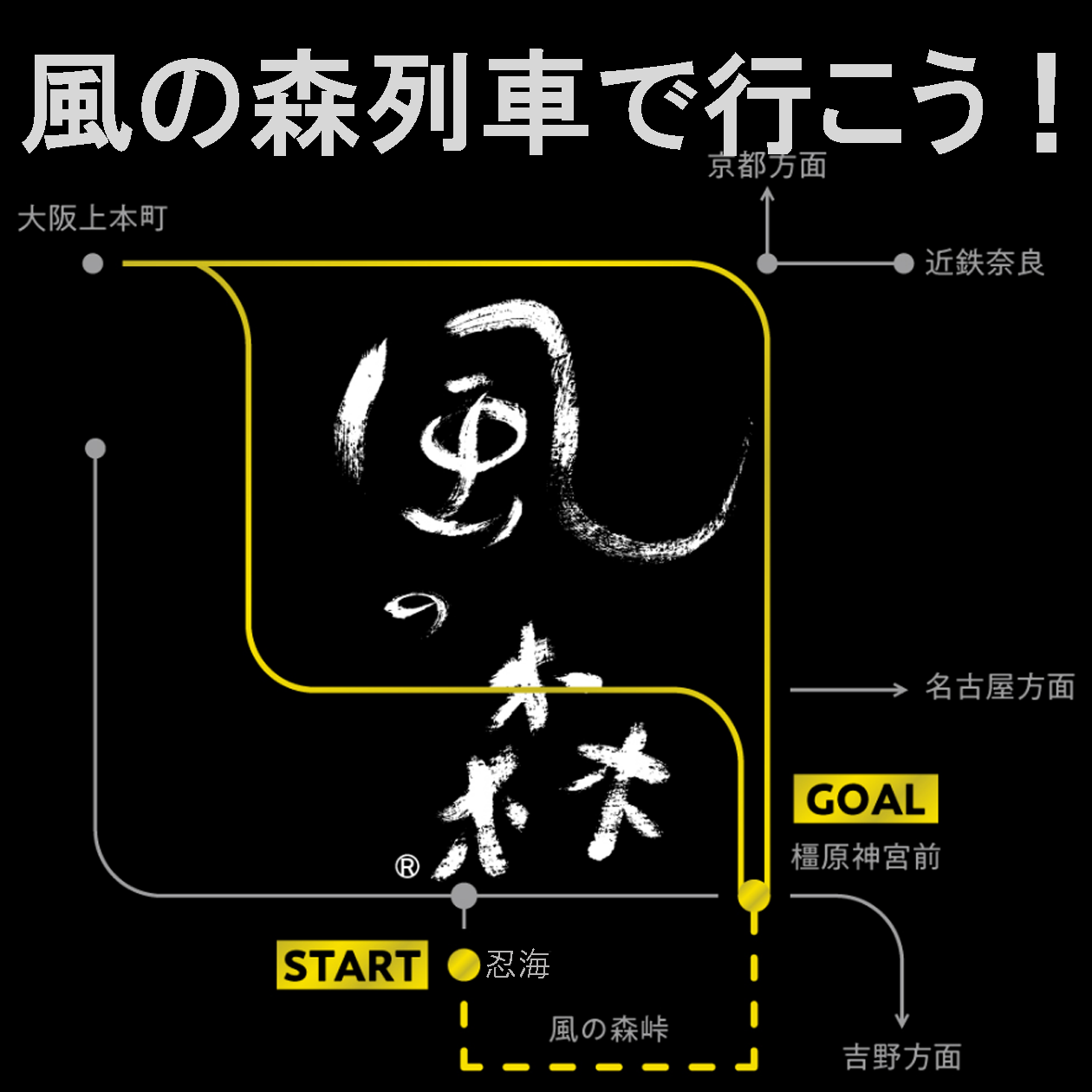

After our special bottling process (described in section above), the sake is transported at sub-zero temperatures and finally kept refrigerated by our retail partners. In this way, not only our efforts at the brewery, but the consideration our transporters and retailers have for quality bears a great influence on the stability and quality of Kaze no Mori.

These measures minimize taste changes before and after bottling which means that consumers of Kaze no Mori not only get to enjoy the tastes and aromas present when a bottle is freshly opened but also the densely rich flavor that remains once the carbon dioxide has evaporated away.

Kaze no Mori is an unpasteurized sake that can be enjoyed slowly for up to a month after opening.

We hope you can enjoy the changes in expression our sakes unveil over time.